News & Notes

The Blog ofMID-CONTINENT STEEL AND WIRE

Steel wire rod is a fundamental material in the construction and manufacturing industries, serving as the backbone for various applications due to its strength and versatility. According to Dr. Henry Malone, a recognized expert in metallurgy, "The quality of steel wire rod directly influences the structural integrity of the products built from it." This emphasizes the critical role that steel wire rod plays in ensuring safety and durability in construction projects, from reinforcing concrete structures to providing essential components in machinery.

In contemporary constructions, steel wire rod is utilized in numerous ways, including the production of wire, nails, and other fasteners essential for assembling frameworks and structures. Its adaptability makes it a preferred choice for engineers and architects who require reliable materials that can withstand various environmental conditions. As technological advancements continue to shape the industry, the methods of processing and utilizing steel wire rod have evolved, allowing for innovations that optimize strength and reduce material waste.

In addition to construction, steel wire rod finds its application in manufacturing, where it is transformed into countless end-products, ranging from springs to automotive components. Its importance cannot be overstated, as it not only contributes to the structural integrity of buildings and machinery but also plays a pivotal role in driving economic growth through various industrial applications. Understanding the nuances of steel wire rod and its uses is essential for professionals looking to enhance their knowledge and practices in these dynamic fields.

Steel wire rod is a crucial raw material in both construction and manufacturing sectors, primarily known for its versatile applications and mechanical properties. Typically produced through the process of hot rolling steel billets, wire rods are available in a variety of diameters ranging from 5.5 mm to 12 mm. According to industry reports, the global steel wire rod market was valued at approximately $400 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.2% through 2030, driven by the rising demand in construction projects and automotive industries.

In construction, steel wire rod serves a multitude of functions. It is primarily utilized in the production of reinforced concrete, where it enhances the tensile strength and overall durability of structures. Additionally, it is employed in manufacturing wire ropes, cables, and other hardware that are integral for scaffolding and support systems in building projects. The American Society for Testing and Materials (ASTM) evaluates these materials and grades them based on their yield strength, which is a critical factor for engineers when designing safe and reliable structures.

Tips: When selecting steel wire rod for a specific project, consider the environmental conditions it will face and the required tensile strength. Always refer to ASTM standards to ensure compliance and safety. Additionally, sourcing from reputable suppliers can greatly reduce the risks associated with subpar materials, ensuring longevity and performance in construction applications. Remember to assess the diameter and grade needed based on your project's specific requirements for optimal results.

| Dimension | Specification | Common Uses | Material Properties |

|---|---|---|---|

| Diameter | 5 mm - 20 mm | Construction reinforcement, wire products | High tensile strength, ductility |

| Length | Up to 1,000 meters | Manufacturing of wires, cables | Good fatigue properties |

| Grade | Low carbon steel, medium carbon steel | Spring manufacturing, fasteners | Corrosion resistance (with proper coating) |

| Surface Treatment | Galvanized, black | Construction, automotive parts | Enhanced durability, weather resistance |

Steel wire rod is a crucial material in construction and manufacturing, primarily due to its unique composition and properties. Typically made from low carbon steel, it contains elements such as manganese and silicon, which enhance its strength and ductility. The standard diameter of wire rods ranges from 5.5 mm to 16 mm, allowing versatility in various applications. This composition not only ensures the rods are strong but also makes them malleable enough to be drawn into wire or used in different forms, providing a wide range of uses in industries.

The properties of steel wire rod further contribute to its importance. It exhibits impressive tensile strength, which is essential for applications that require durability, such as reinforcing concrete and producing mesh for construction. Additionally, steel wire rods are resistant to deformation under load, which helps maintain structural integrity over time. The surface finish of the rods may also vary, influencing their performance in different environments, particularly in terms of corrosion resistance. This adaptability makes steel wire rods a preferred choice in many construction and manufacturing projects.

Steel wire rod is a crucial product in the construction and manufacturing sectors, primarily produced through several key manufacturing processes. The first step in creating steel wire rod typically involves the melting and refining of raw steel. This molten steel is then cast into large billets or blooms, which are subsequently reheated and rolled through a series of stands in a rolling mill. This method not only shapes the steel but also enhances its mechanical properties.

After the initial rolling process, the wire rod undergoes additional processing, such as drawing and heat treatment, to achieve the desired diameter and strength characteristics. Wire drawing involves pulling the steel rod through a series of progressively smaller dies to reduce its diameter while increasing its tensile strength. This process is vital for producing wire products used in a variety of applications, such as reinforcement in concrete construction, manufacturing of cables, and making fasteners. Throughout these processes, quality control measures are implemented to ensure the steel meets specific industry standards, ensuring its longevity and performance in various applications.

Steel wire rod is a versatile material widely utilized in various construction and manufacturing applications due to its strength and durability. In construction, it serves as a fundamental component in reinforced concrete, where it is transformed into steel reinforcement bars or rebar. These rods significantly enhance the tensile strength of concrete structures, ensuring they can withstand heavy loads and resist cracking under stress. The integration of steel wire rod in concrete not only prolongs the lifespan of buildings and infrastructure but also allows for more innovative architectural designs.

Beyond reinforcement, steel wire rod is used in the manufacturing of a range of construction materials. It can be processed into wire mesh, which provides additional support and stability in concrete applications, particularly in slabs, walls, and foundations. Additionally, the rod can be drawn into smaller diameters to create tie wires, which are essential for securing rebar in place during the pouring of concrete. The adaptability of steel wire rod makes it a critical resource in ensuring the efficiency and safety of construction projects, highlighting its importance in modern engineering practices.

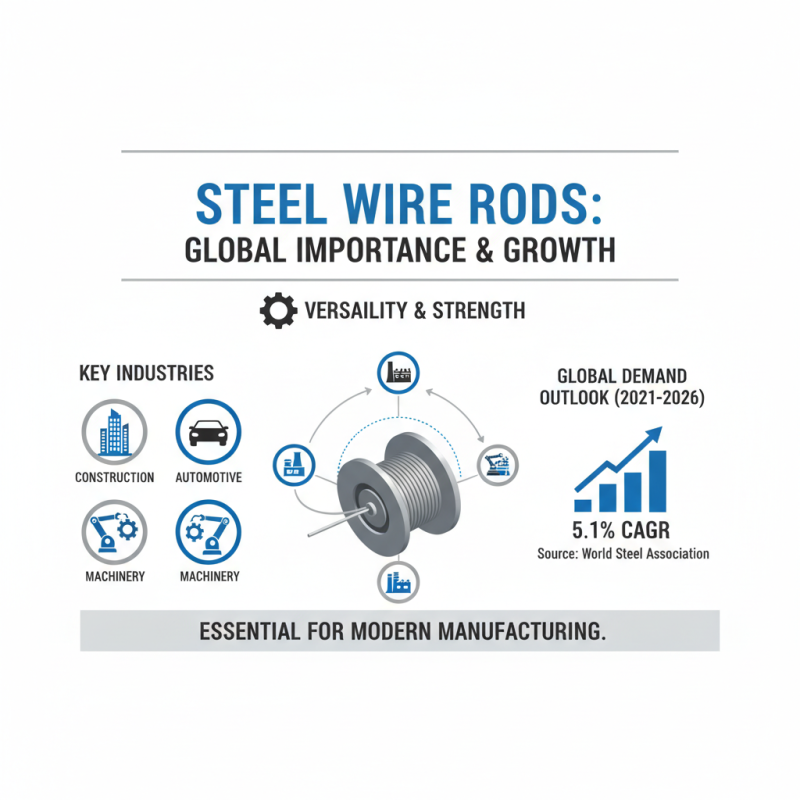

Steel wire rod, characterized by its versatility and strength, plays a crucial role in various manufacturing industries. Derived from the process of drawing steel into thin wires, steel wire rods are transformed into products essential for construction, automotive, and machinery sectors. According to a report by the World Steel Association, the global demand for steel wire products is projected to grow steadily, with an expected compound annual growth rate (CAGR) of 5.1% from 2021 to 2026, highlighting its importance in modern manufacturing.

In construction, steel wire rods are primarily used to produce reinforcement bars, known as rebar, which strengthen concrete structures. The American Concrete Institute indicates that approximately 70% of steel wire rods produced are utilized in concrete reinforcement, underscoring their significance in enhancing structural integrity. Additionally, these rods are also employed in the fabrication of wire products like mesh and fencing, contributing to safety and durability in construction projects.

Moreover, in the automotive industry, steel wire rods are processed into components such as suspension springs and wire harnesses. The global automotive wire and cable market is forecasted to reach USD 53.3 billion by 2025, driven by the increasing demand for lightweight materials that ensure efficiency and performance. Overall, the applications of steel wire rods in manufacturing industries are extensive and vital for maintaining the quality and safety of various end products.

If you need more information about our products or you can’t find what you are looking for, please reach us via our contact form and we will get back to you as soon as possible.

© 2022 MID-CONTINENT STEEL AND WIRE, ALL RIGHTS RESERVED | PRIVACY POLICY | PRIVACY POLICY – CALIFORNIA