News & Notes

The Blog ofMID-CONTINENT STEEL AND WIRE

Industrial rebar is a vital component in construction. Its role cannot be understated. This material, often made from steel, provides the necessary support for concrete structures. Concrete alone has limitations. It excels in compression but struggles with tensile strength. Here, industrial rebar comes into play.

When integrated into concrete, industrial rebar transforms the structural integrity of buildings, bridges, and roads. This integration improves resistance to various stresses. Without it, many structures could face early deterioration or failure. However, quality matters. Not all rebar is created equal. Specifications must be met.

Despite its importance, many overlook the need for proper installation and inspection. Flaws in placement can lead to catastrophic results. It raises questions about current practices. Reliable resources exist, yet the industry still grapples with inconsistent standards. Understanding industrial rebar is crucial for anyone in the construction field. It paves the way for safer, more durable infrastructures.

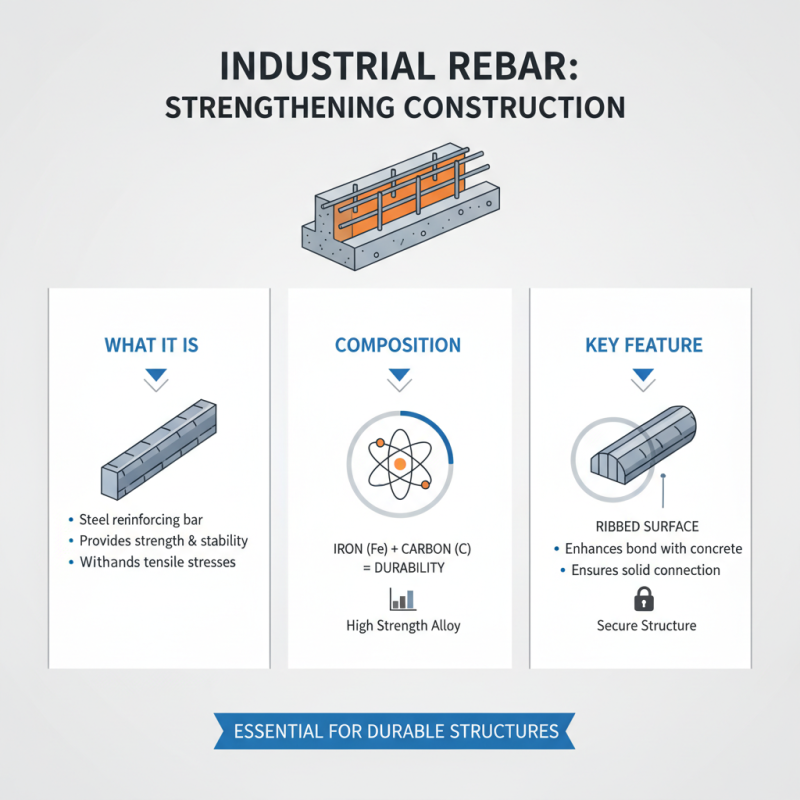

Industrial rebar, or reinforcing bar, is essential in construction. It provides strength and stability to various structures. Typically made of steel, industrial rebar is designed to withstand tensile stresses. Its composition includes a combination of iron and carbon, giving it durability. The ribs on its surface enhance the bond with concrete, ensuring a solid connection.

The manufacturing process is not flawless. Sometimes, the quality can vary due to different factors. Miscalculations in the material mix can lead to weaker bars. These issues must be examined carefully during production. Flawed rebar can compromise the integrity of buildings and bridges, causing safety concerns.

In construction, proper selection of industrial rebar is vital. Engineers must assess the specific needs of each project. Factors like load-bearing requirements and environmental conditions play a crucial role. The right choice can prevent costly repairs and ensure long-lasting structures. It's a complex task that demands attention to detail.

Rebar, or reinforcing bar, has roots that date back to ancient construction methods. The Romans used iron bars in their concrete structures. This pioneering use was a breakthrough, combining strength and durability. Over the years, as construction techniques evolved, so did the materials used to strengthen concrete.

In the late 19th century, the modern version of rebar emerged. Engineers realized that steel could significantly enhance concrete’s tensile strength. This shift was crucial during industrialization. Skyscrapers began to rise, showcasing the new possibilities of combining steel and concrete. Yet, challenges persisted. Corrosion became a pressing issue. Builders often faced the dilemma of balancing cost with quality.

Today, industrial rebar is vital to safe construction, yet not without its flaws. While it improves structural integrity, improper placement can lead to failures. Learning from past mistakes is essential. Each project presents lessons that can refine techniques and materials, ensuring that rebar continues to play a key role in safe, durable construction.

Industrial rebar plays a crucial role in modern construction projects. It provides the strength necessary for structural integrity. Builders use it to reinforce concrete structures, ensuring they withstand various stresses. Large commercial buildings and bridges often rely on steel rebar to endure heavy loads and natural forces.

In addition to high-rise buildings, industrial rebar is essential in road construction. Reinforced concrete roads can handle the weight of vehicles better. This application reduces maintenance needs over time. In residential projects, rebar enhances the durability of foundations and walls. Proper placement of rebar can prevent cracking and shifting.

However, many construction teams sometimes overlook rebar placement. Improper installation can lead to failures down the line. That's a risk that should not be taken lightly. Regular inspections are essential to maintain safety standards. Engineers must ensure that they precisely meet design specifications. Overlooking these can create costly issues.

Industrial rebar, also known as reinforcing bar, plays a crucial role in construction projects. Its main purpose is to strengthen concrete structures, which alone can be weak under tension. We often see it in bridges, buildings, and highways—key components that need durability. Without rebar, these structures may suffer from cracking and fail over time.

The benefits of using industrial rebar are significant. It helps in distributing loads evenly, which improves structural integrity. This reinforcement can withstand various environmental factors, such as wind and seismic activity. Yet, not all rebar is created equal. Some projects overlook grade specifications, leading to potential weaknesses. This oversight can compromise safety, making proper selection essential.

Proper installation is also critical. Workers must ensure that the rebar is placed correctly and tied securely. Mistakes in this process can lead to catastrophic failures down the line. It's important to monitor the construction process closely. On-site inspections often reveal issues that need addressing. This vigilance not only ensures compliance but also enhances the long-term performance of the structure.

Industrial rebar, a critical component in construction, is subject to various standards and regulations. These frameworks ensure safety and structural integrity across projects. In the U.S., the American Concrete Institute (ACI) and ASTM International set forth guidelines that govern the quality and specifications of rebar. For instance, ASTM A615 highlights the essential properties of carbon steel rebar, including tensile strength and ductility. Adhering to these standards helps prevent catastrophic failures in construction.

Another important aspect is regional code compliance. Building codes vary by location, often aligning with international standards like Eurocode. These codes detail dimensions, yield strengths, and types of bar grades. For example, Grade 60 rebar is often mandated in seismic regions for its high tensile strength and flexibility. Construction professionals must stay updated on these regulations to avoid costly penalties and ensure protection against non-compliance.

Tips: Always check local regulations before starting a project. Familiarize yourself with the relevant standards for your area. Consider attending industry seminars to keep your knowledge current. Understanding codes is essential for any construction professional. It enables safer, more efficient practices.

If you need more information about our products or you can’t find what you are looking for, please reach us via our contact form and we will get back to you as soon as possible.

© 2022 MID-CONTINENT STEEL AND WIRE, ALL RIGHTS RESERVED | PRIVACY POLICY | PRIVACY POLICY – CALIFORNIA