News & Notes

The Blog ofMID-CONTINENT STEEL AND WIRE

When embarking on a project that requires the use of steel and wire, making informed decisions is paramount to ensure both structural integrity and cost-effectiveness. According to a report by the World Steel Association, global steel demand is projected to reach 1.8 billion metric tons by 2025, driven by the increasing need for robust construction materials across various sectors. Given this rising demand, the selection of appropriate steel and wire becomes a critical factor that can significantly impact the success of your project.

The nuances of choosing the right type of steel and wire are multifaceted, encompassing considerations such as tensile strength, corrosion resistance, and the specific requirements of your application. A study from Smithers Pira indicates that the wire industry is poised for steady growth, with an expected annual increase of 4.5% over the next five years. This underscores the importance of understanding market trends, specifications, and standards in order to select materials that not only meet performance benchmarks but also align with budgetary constraints. As projects become increasingly complex, leveraging expert knowledge in steel and wire selection is essential to achieving optimal outcomes.

When selecting the right steel and wire for a project, understanding the different types of steel available is crucial. The two primary categories of steel are carbon steel and alloy steel, each offering unique properties and applications. Carbon steel, which contains varying amounts of carbon, is known for its strength and hardness, making it suitable for construction and manufacturing applications. According to the World Steel Association, carbon steel accounts for about 90% of global steel production, highlighting its significance in the industry.

On the other hand, alloy steel incorporates various alloying elements, such as chromium, nickel, and molybdenum, to enhance specific characteristics, including corrosion resistance and toughness. This type of steel is favored in high-stress applications, particularly in automotive and aerospace industries. Reports from the American Iron and Steel Institute indicate that the demand for alloy steel has increased by over 15% in recent years, driven by advancements in technology and the need for more durable materials. Understanding these distinctions and the application environments for each type of steel enables manufacturers and builders to make informed decisions that align with their project requirements.

When selecting steel and wire for your project, understanding the mechanical properties is crucial, particularly tensile strength and ductility. Tensile strength is a measure of the maximum amount of tensile (stretching) stress that a material can withstand before failing. For projects requiring high load-bearing capacity, opting for materials with high tensile strength is essential. This ensures that the steel or wire can hold up under strain without breaking, making it a vital factor in construction, manufacturing, and engineering applications.

Ductility, on the other hand, refers to the ability of a material to deform under tensile stress. A ductile material will stretch or bend rather than break when subjected to forces, which is particularly advantageous in dynamic environments that involve vibrations or shocks. When evaluating materials, considering both tensile strength and ductility allows for a balanced choice that aligns with the specific demands of your project. High ductility can prevent catastrophic failures, giving engineers and builders peace of mind as they design structures that can withstand a variety of conditions. Therefore, careful assessment of these mechanical properties will guide you to the most suitable steel or wire options for your needs.

| Material Type | Tensile Strength (MPa) | Ductility (% Elongation) | Common Applications |

|---|---|---|---|

| Low Carbon Steel | 370 - 700 | 20 - 40 | Automotive parts, Structural applications |

| Medium Carbon Steel | 570 - 900 | 16 - 30 | Gears, Axles |

| High Carbon Steel | 850 - 1200 | 6 - 14 | Cutting tools, Springs |

| Stainless Steel | 520 - 2000 | 5 - 40 | Pipes, Kitchen utensils |

| Aluminum Alloy | 200 - 600 | 8 - 25 | Aerospace components, Packaging |

| Copper Wire | 210 - 400 | 30 - 50 | Electrical wiring, Plumbing |

| Titanium Alloy | 900 - 1400 | 10 - 30 | Medical implants, Aerospace |

| Galvanized Steel | 400 - 700 | 15 - 30 | Construction, Fencing |

| Spring Steel | 800 - 1200 | 7 - 18 | Springs, Shock absorbers |

| Repair Wire (Welding) | 350 - 780 | 15 - 35 | Welding applications, Repair work |

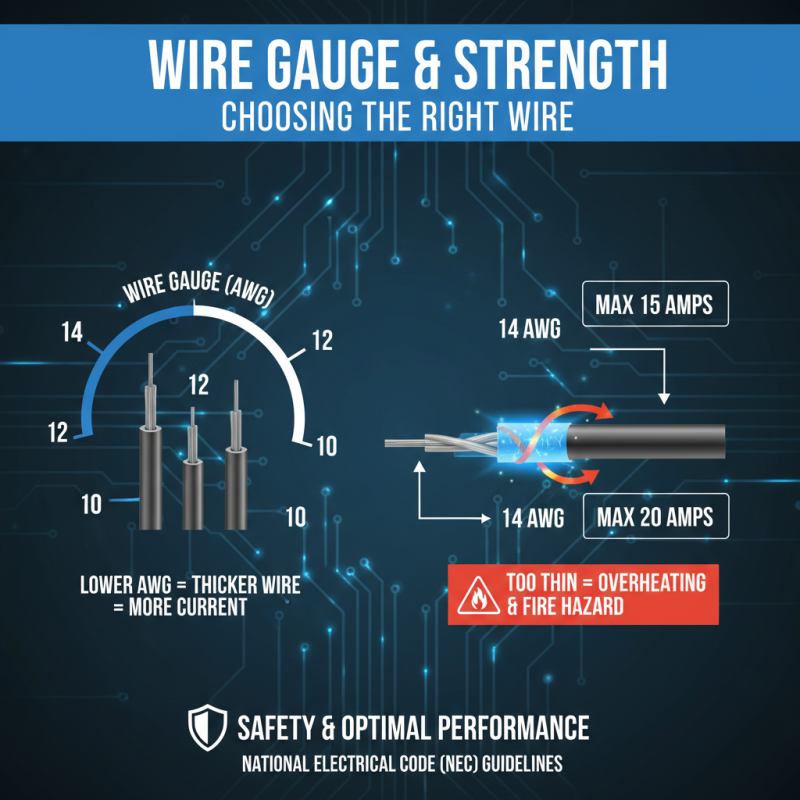

When selecting the right wire for your project, understanding wire gauge and strength is crucial for ensuring optimal performance and safety. Wire gauge, typically measured in American Wire Gauge (AWG), directly influences the wire's current-carrying capacity and resistance. According to a report by the National Electrical Code (NEC), using the correct gauge can prevent overheating and potential fire hazards, as a wire that is too thin for the intended load can generate excess heat due to increased resistance. For instance, a 14 AWG wire can safely carry up to 15 amps of current, while a 12 AWG wire is suitable for up to 20 amps, making the choice of gauge essential in high-load situations.

Strength is another critical factor influenced by the wire's material composition and diameter. Steel, for instance, offers high tensile strength, making it ideal for construction and structural applications. A study by the American Society of Civil Engineers indicates that using high-strength steel wire can enhance load-bearing capabilities by up to 30%, which translates to safer and more durable structures. Conversely, for applications where flexibility and corrosion resistance are essential, stainless steel or copper wire may be better suited, despite lower tensile strength. The right wire selection not only ensures the integrity of your project but also optimizes performance based on specific project requirements.

When selecting steel and wire for your project, the corrosion resistance of the materials is a crucial factor that directly impacts the longevity and performance of the finished product. Corrosion can lead to significant structural deterioration, making it essential to choose materials that can withstand exposure to environmental factors such as moisture, chemicals, and pollutants. One of the most effective ways to enhance corrosion resistance is through coatings. Various coatings, such as galvanization, powder coating, or paints, can protect against moisture and chemical exposure, thereby prolonging the life of the steel or wire.

In addition to coatings, the choice of alloy can greatly affect durability. Different steel alloys possess unique properties that enhance their resilience against corrosion. For instance, stainless steel is known for its exceptional resistance to rust and tarnishing due to the addition of chromium, which forms a protective oxide layer on the surface. Similarly, other alloying elements, like nickel and molybdenum, can further improve resistance in harsh conditions. When evaluating materials for your project, consider not only the coating options but also the specific alloy compositions that will best suit the environmental challenges it may face. By prioritizing both coatings and alloy properties, you can ensure a more durable and reliable outcome for your project.

When it comes to selecting steel and wire for your projects, achieving a balance between cost-effectiveness and quality is paramount. While it may be tempting to opt for the cheapest option available, this approach can often lead to increased expenses down the line due to failures or the need for replacements.

It's crucial to assess the specific requirements of your project carefully, including load-bearing capacities and environmental factors. Investing in higher-quality materials may involve a larger initial expenditure, but it can save time and money in the long run by minimizing the risk of structural failures.

Additionally, understanding the different grades and types of steel and wire can significantly impact your overall budget. Each material has its unique properties that contribute to its performance, and selecting the right one can help avoid costly mistakes. For example, specialized steel may offer better durability in harsh environments, which could reduce maintenance costs.

By conducting thorough research and consulting with professionals, you can make informed decisions that align both with your financial constraints and the long-term integrity of your project. This strategic approach ensures that you meet your project needs without compromising on safety or quality.

If you need more information about our products or you can’t find what you are looking for, please reach us via our contact form and we will get back to you as soon as possible.

© 2022 MID-CONTINENT STEEL AND WIRE, ALL RIGHTS RESERVED | PRIVACY POLICY | PRIVACY POLICY – CALIFORNIA