News & Notes

The Blog ofMID-CONTINENT STEEL AND WIRE

In the ever-evolving landscape of construction and manufacturing, the significance of selecting the right materials cannot be overstated. Steel wire, a fundamental component in various applications, plays a pivotal role in ensuring structural integrity, durability, and overall project success. As industry expert Dr. Emily Carter articulates, “The choice of steel wire is not just a technical decision; it impacts the longevity and safety of the entire project.” This statement underscores the importance of carefully considering the specific requirements of each project when selecting steel wire.

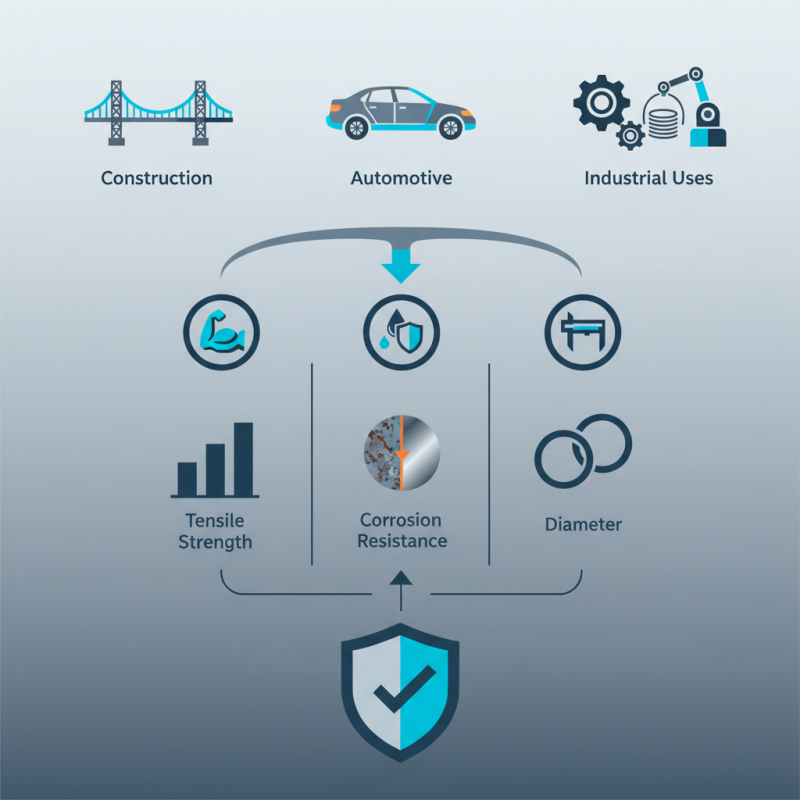

Choosing the best steel wire involves understanding various factors, including tensile strength, corrosion resistance, and diameter. Each project may demand unique characteristics tailored to its specific applications, whether it be for construction, automotive, or industrial uses. As we delve into the critical aspects of steel wire selection in this guide, we aim to equip you with the knowledge necessary to make informed decisions that align with your project goals. By examining the key attributes and industry standards, this outline will serve as a comprehensive resource for selecting the optimal steel wire for your needs.

When selecting the best steel wire for your projects, it is crucial to understand the different types available and their specific applications. Steel wires come in various grades and thicknesses, each designed to meet unique demands. For instance, stainless steel wire is highly resistant to corrosion, making it ideal for outdoor structures and marine environments. Similarly, high carbon steel wire boasts a greater tensile strength, which is essential for load-bearing applications such as suspension bridges or construction reinforcements.

In addition to material properties, the wire's structure plays a significant role in its suitability for certain tasks. For example, stranded wire, made up of multiple filaments twisted together, offers flexibility and is often used in situations where bending or movement is required. On the other hand, solid wire provides more rigidity, suited for fixed installations like fencing or support frameworks. Understanding the different wire types, including their finishes and coatings, enables you to choose the most effective steel wire that not only fits your project’s requirements but also enhances durability and performance.

When selecting steel wire for your projects, several key properties should be considered to ensure optimal performance and suitability for your specific application. Firstly, the wire’s tensile strength is critical. This property indicates how much force the wire can withstand before breaking. Higher tensile strength is essential for projects that involve heavy loads or require durability under stress.

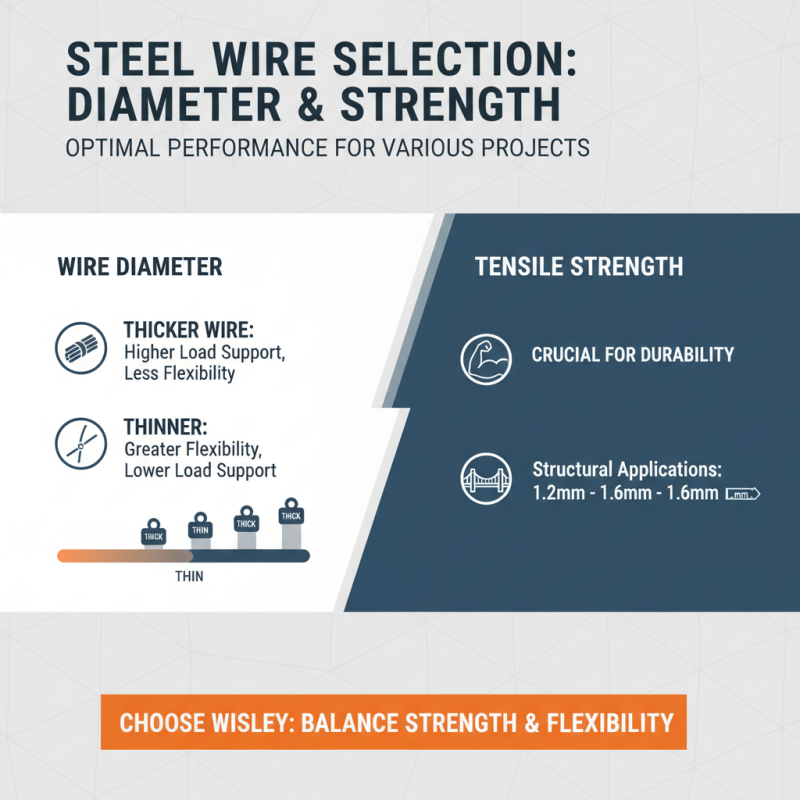

Another important factor to evaluate is the diameter of the wire. Thicker wires can bear more weight and resist deformation, yet they may also be less flexible. Conversely, thinner wires offer better flexibility but at the cost of strength. Therefore, it’s vital to match the wire diameter with the demands of your project to prevent potential failures.

Tips: When choosing steel wire, consider using a wire with corrosion resistance for outdoor or humid environments. Look for options like galvanized or stainless steel to extend the lifespan of your project. Additionally, evaluate the wire's elasticity; a wire that can stretch slightly under load may perform better in dynamic settings, reducing the risk of sudden breakage. Always assess your project requirements carefully to make an informed choice that ensures safety and reliability.

When choosing the best steel wire for your projects, understanding various steel grades and their specific applications is crucial. Steel wire comes in different grades, each designed to withstand unique conditions and stresses. For instance, high-carbon steel wire is known for its strength and is often used in applications where high tensile strength is essential, such as for cables and springs. Conversely, low-carbon steel wire provides greater flexibility and is suitable for applications like fencing and binding.

Tips: Always consider the environmental factors related to your project. If the steel wire will be exposed to moisture or harsh chemicals, opting for corrosion-resistant grades, such as galvanized steel wire, can significantly enhance the longevity of your project.

Another important factor is the diameter of the wire. Thicker wires generally offer increased strength but may be less flexible, making them ideal for structural applications. For tasks that require bending and shaping, thinner wires might be more appropriate. Understanding the balance between strength and flexibility will help ensure you select the right grade for your specific needs.

Tips: Conduct a stress analysis of your project to determine the necessary wire grade. This proactive approach can help avoid costly mistakes and ensure that you choose the most suitable steel wire for your application.

When selecting steel wire for various projects, understanding wire diameter and strength is crucial for achieving optimal performance. Wire diameter not only affects the tensile strength but also influences the overall durability of the application. According to industry reports, a thicker wire generally supports higher loads but may sacrifice flexibility, making it essential to evaluate the specific demands of your project. For instance, a wire diameter ranging from 1.2 mm to 1.6 mm is often preferred for structural applications, as it combines strength and flexibility effectively.

Tips: Always consider the load-bearing requirements of your project before finalizing the wire diameter. Utilizing a wire gauge chart can aid in making comparisons between different sizes, ensuring you select the most appropriate option for your needs. Additionally, the tensile strength of steel wires can vary based on the wire's material composition and processing method, so it is advisable to consult technical data sheets for precise values.

Strength is measured in terms of tensile and yield strength. For example, high-carbon steel wires typically exhibit tensile strengths between 1500 to 2000 MPa, making them suitable for demanding applications like construction and automotive industries. Understanding these metrics helps in selecting a wire that not only meets but exceeds performance expectations while maintaining safety standards in your projects.

Tips: When assessing wire strength, consider environmental factors—such as exposure to chemicals and high temperatures—that may affect performance over time. This foresight can significantly enhance the longevity and reliability of your projects.

When sourcing quality steel wire for your projects, it’s crucial to understand the specific requirements of your applications. Begin by determining the type of steel wire you need based on factors such as tensile strength, flexibility, and corrosion resistance. Different projects may require different grades and coatings of steel wire, so it’s essential to assess your project’s demands carefully. Gathering technical specifications, such as wire diameter and load-bearing capacity, will aid you in selecting a product that meets safety and performance standards.

Buying from reputable suppliers is another key aspect of the sourcing process. Research potential suppliers and evaluate their production methods, quality control standards, and customer feedback. A supplier that prioritizes quality assurance will likely offer better, more reliable products. Additionally, requesting samples can provide insight into the wire’s performance and durability before making a bulk purchase. By taking these steps, you can ensure that you are investing in high-quality steel wire that will meet the needs of your projects effectively.

If you need more information about our products or you can’t find what you are looking for, please reach us via our contact form and we will get back to you as soon as possible.

© 2022 MID-CONTINENT STEEL AND WIRE, ALL RIGHTS RESERVED | PRIVACY POLICY | PRIVACY POLICY – CALIFORNIA