News & Notes

The Blog ofMID-CONTINENT STEEL AND WIRE

Selecting the appropriate steel rod for a construction project is crucial for ensuring structural integrity and durability. According to the World Steel Association, the global demand for steel is projected to reach approximately 1.9 billion metric tons by 2025, emphasizing the significance of choosing high-quality materials. Steel rods, an essential component in concrete reinforcement, play a vital role in enhancing the strength of structures, making informed decisions during procurement all the more essential.

Industry expert Dr. Emily Tran, a renowned civil engineer at Steel Innovations Group, emphasizes that "the right steel rod not only fortifies the framework of a structure but also optimizes the overall performance and longevity." With various types of steel rods available on the market, each tailored for specific applications and conditions, understanding the standards and specifications becomes imperative. Factors such as yield strength, ductility, and resistance to corrosion must be carefully considered to achieve the best results in any construction endeavor. As we delve deeper into the selection process, this guide will elucidate essential criteria to ensure the right choice of steel rod for your next project.

When embarking on a construction project, selecting the appropriate steel rod is crucial for ensuring structural integrity and longevity. Different types of steel rods, such as deformed and mild steel rebar, serve distinct purposes and should be chosen based on the specific requirements of the project. According to current market reports, the global steel rebar market is projected to reach USD 268.4 billion by 2030, with a compound annual growth rate (CAGR) of 4.0%. Understanding the differences in steel rod types, including their manufacturing processes and coating options, is essential for making informed decisions.

Market dynamics also influence prices and availability, as seen in regions like Nigeria where steel rod prices have surged by up to 210% over the past two years. This rise can be attributed to various factors, including manufacturing costs and trade tariffs. Moreover, advancements in technology, such as the automation of steel bar work, enable more efficient reinforcement assembly, allowing for complex designs without compromising on structural performance. As you navigate your construction project, keeping these industry trends and technical considerations in mind will be pivotal in selecting the right steel rod.

| Type of Steel Rod | Diameter (mm) | Tensile Strength (MPa) | Typical Use Cases |

|---|---|---|---|

| Mild Steel Rod | 10 - 40 | 250 - 400 | General construction, frameworks |

| High Tensile Steel Rod | 8 - 32 | 500 - 700 | Heavy construction, bridges |

| Rebar (Reinforcing Bar) | 10 - 50 | 400 - 600 | Concrete reinforcement, slabs |

| Stainless Steel Rod | 5 - 25 | 520 - 820 | Corrosion resistance, architectural uses |

| Carbon Steel Rod | 6 - 30 | 350 - 600 | Manufacturing, general machinery |

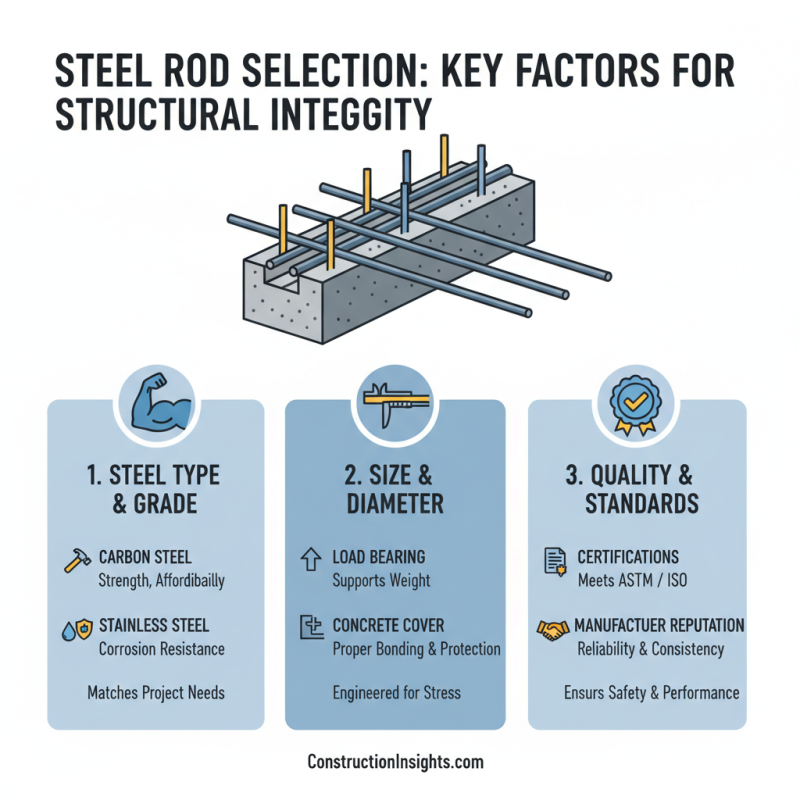

When selecting steel rods for your construction project, several key factors must be considered to ensure structural integrity. First and foremost, the type of steel is crucial. Different grades of steel, such as carbon steel or stainless steel, offer varying levels of strength, durability, and resistance to environmental factors like corrosion. Understanding the specific requirements of your project will guide you in choosing the appropriate grade to meet both safety and performance standards.

Another important factor is the diameter and length of the steel rods. The dimensions will directly impact the load-bearing capacity and flexibility of the structure. It is essential to analyze the structural requirements and the forces that will act upon the rods. Additionally, consider local building codes and regulations, as they may dictate specific requirements regarding the types and sizes of steel rods that can be used. By taking these factors into account, you can select steel rods that will provide the necessary support and stability for your construction project.

When evaluating the cost-effectiveness of various steel rod options for construction projects, it is crucial to understand the balance between upfront costs and long-term performance. According to the Steel Construction Institute, when selecting steel rods, factors such as tensile strength, yield strength, and corrosion resistance significantly influence both initial investment and durability.

For instance, high-strength low-alloy steel rods often have a higher initial cost but can result in substantial savings over time due to their performance under stress and reduced need for maintenance.

Tips: Always consider the specific requirements of your project when selecting steel grades. For example, if your project is located in a coastal environment, opting for stainless steel or galvanized rods may seem more expensive initially but can offer long-term savings through reduced corrosion-related repairs.

Additionally, it's worth noting that the cost of raw materials can fluctuate significantly. The World Steel Association reported that the price of steel has seen variations of up to 30% in recent years due to global demand and supply chain issues. Therefore, it’s advisable to keep abreast of market trends and consider bulk purchasing options to mitigate costs effectively. Analyzing different suppliers is equally important to ensure you're getting the best quality for your investment.

When selecting the right steel rod for your construction project, it's crucial to consider industry standards and regulations. Steel rods are categorized based on their grade, which affects their strength, ductility, and suitability for various applications. The American Society for Testing and Materials (ASTM) provides guidelines that help determine which type of steel rod meets the necessary structural integrity for your specific needs. Compliance with these standards ensures not only safety but also the longevity of the structure.

Tips: Always verify that the steel rods you purchase are certified to meet the relevant ASTM specifications. Additionally, consider the environmental factors that may affect the steel's performance, such as corrosion potential in coastal areas.

Furthermore, local building codes might impose additional requirements beyond standard regulations. It's essential to consult with engineering professionals familiar with local regulations and ensure that your choice of steel rods aligns with these codes to avoid costly rework or structural failures.

Tips: Engage with local suppliers who are knowledgeable about the latest regulations to get updated information on material availability and compliance issues. This proactive approach can save time and resources in the long run.

When embarking on a construction project, selecting the right steel rod is crucial, as the specifications directly impact the overall durability of the structure. Different grades of steel rods, such as mild steel and high-strength deformed bars, possess varying tensile strengths and corrosion resistance. For instance, high-strength steel rods are typically preferred for high-load applications as they provide enhanced performance under stress, ensuring the longevity of the project.

Additionally, the diameter and length of the steel rods must be carefully considered. Thicker rods can bear more weight but may also require more substantial load-bearing designs. Conversely, using thinner rods can lighten the overall structure but may compromise its strength.

Moreover, environmental factors play a significant role; regions prone to moisture may necessitate galvanized or epoxy-coated steel to prevent rusting, thus ensuring the integrity of the construction over time. Therefore, understanding these specifications not only aids in the selection process but also significantly influences the durability and safety of the finished project.

If you need more information about our products or you can’t find what you are looking for, please reach us via our contact form and we will get back to you as soon as possible.

© 2022 MID-CONTINENT STEEL AND WIRE, ALL RIGHTS RESERVED | PRIVACY POLICY | PRIVACY POLICY – CALIFORNIA