News & Notes

The Blog ofMID-CONTINENT STEEL AND WIRE

When planning your next project, the choice of quality steel can make or break its success. Quality steel is essential for durability and performance. In 2026, various options will be available to ensure you select the best material for your needs.

Exploring these options might seem straightforward; however, it can be overwhelming. Different types of steel serve different purposes. Understanding their properties is crucial. Not every steel type is equal. Some may not meet your specific requirements, leading to potential issues down the line.

Finding the right quality steel also involves considering its availability and cost. The best material isn’t always the most expensive. You might need to juggle your budget while ensuring quality. The right choice can enhance your project’s longevity. Inadequate research could result in regrettable decisions. Stay informed about the latest developments in steel technology and trends.

Steel has become an essential material in construction. Its strength and versatility are unmatched. Various types of steel cater to different applications in building projects. Carbon steel is a popular choice for structural frameworks. It offers durability while remaining cost-effective. Stainless steel, known for its corrosion resistance, is ideal for environments exposed to moisture.

Reinforced steel bars, or rebar, enhance concrete structures. They improve tensile strength, making buildings safer and longer-lasting. However, choosing the right type of steel can be daunting. Each project has unique requirements and site conditions. Misjudging the steel type can lead to costly repairs or structural failures.

Welded steel beams are preferred for large-scale projects. They provide excellent load-bearing capabilities. But they require skilled labor for installation. This is a challenge many projects face. There’s always room for improvement in material selection and application. Understanding specific needs can lead to better outcomes.

When selecting steel for your next project, it's vital to consider key properties such as strength, durability, and compliance. High-quality steel can withstand high stress and extreme environments, making it an ideal choice for various applications. According to industry reports, steels like S355 and S690 offer yield strengths of 355 MPa and 690 MPa, respectively. These figures highlight their ability to support heavy loads while maintaining structural integrity.

Durability is another essential factor. Quality steel must resist corrosion over time. For example, weathering steel, like ASTM A588, develops a protective layer of rust, which enhances its longevity. This property can save costs on maintenance and replacements. However, choosing the right steel requires careful consideration of environments it will face, as not all steel grades are suitable for every condition.

Compliance with industry standards is crucial as well. High-quality steel must meet specific regulations for safety and performance. Reports indicate that non-compliance can lead to failures in construction, endangering lives and costing companies significantly. It’s essential to conduct thorough research and ensure that selected steel adheres to the necessary codes. Each project presents unique challenges that demand keen insight into the properties of the materials used.

When selecting steel for construction, it's essential to understand different grades' properties. Steel grades vary widely in strength, flexibility, and resistance to corrosion. For example, structural steel, like ASTM A36, is well-known for its strong properties. It has a minimum yield strength of 36,000 psi, making it suitable for buildings and bridges. However, this strength comes at the expense of ductility, which can be a concern in seismic zones.

On the other hand, high-strength low-alloy (HSLA) steels, such as ASTM A572, offer a better combination of strength and ductility. With yield strengths from 36,000 to 65,000 psi, HSLA steels are often preferred in construction projects requiring resilience. Yet, these steels can be costlier and may require careful fabrication processes. Furthermore, engineers must evaluate the potential for weldability issues that can arise with certain grades.

While stainless steel is favored for its corrosion resistance, its higher cost can deter usage in large projects. Industry reports indicate that stainless steel's market can increase by 3% annually, emphasizing its growing importance. Yet, the choice often hinges on the project's specific needs, including budget constraints and environmental factors. Balancing performance with cost is not always straightforward, and each project may reveal new challenges.

Innovative steel treatments have revolutionized the construction and manufacturing industries. These treatments improve strength, corrosion resistance, and overall performance. One example is heat treatment, which alters the material's internal structure. This process can create steel products that are significantly stronger and more durable. The result? Enhanced longevity and reduced maintenance costs for your projects.

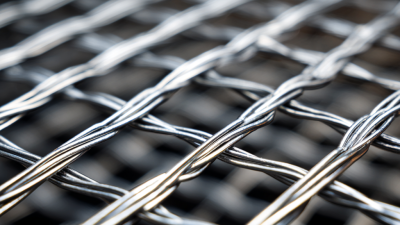

Another effective method is surface hardening. Techniques like nitriding and carburizing provide a tougher outer layer on steel. This approach is particularly beneficial in high-wear applications where friction is a concern. The challenge lies in applying these treatments uniformly. Inconsistencies can lead to weak points, affecting the performance of the final product.

Finally, protective coatings have gained popularity. These coatings can add an extra layer of defense against environmental factors. However, selecting the right coating and ensuring proper application is critical. A mismatched coating may fail to adhere, leading to premature rust or failure. This highlights the importance of thorough testing and evaluation in your steel options.

As sustainability becomes a priority, eco-friendly steel options are crucial for future projects. Traditional steel production involves high carbon emissions and resource depletion. However, innovative techniques and materials are emerging. For instance, using recycled steel significantly reduces the carbon footprint. Incorporating up to 90% recycled content in steel can save energy. It’s a viable option that many construction projects can adopt.

Another exciting avenue is green steel, produced through renewable energy sources. This method minimizes harmful emissions. It often relies on hydrogen instead of coal, a promising shift for the industry. While these options are on the rise, they may still face challenges. The current infrastructure may not support widespread use yet. Transitioning to completely sustainable materials requires time and investment.

Exploring these options helps tackle pressing environmental issues. However, it’s essential to reflect on their availability and cost. Eco-friendly solutions may initially seem expensive. Yet, considering long-term sustainability is key. We must continue to seek balance between quality and environmental impact. This journey is still in its early stages, but the future of steel can be greener.

If you need more information about our products or you can’t find what you are looking for, please reach us via our contact form and we will get back to you as soon as possible.

© 2022 MID-CONTINENT STEEL AND WIRE, ALL RIGHTS RESERVED | PRIVACY POLICY | PRIVACY POLICY – CALIFORNIA